Trusted Inventory Intelligence

6× faster inventory monitoring at 10× lower cost, powered by:

TINAMU Tools, Automation, and Analytics.

Swiss precision for global application

Real-Time & Accurate

TINAMU Analytics for 99% accurate results in <2h after scanning

Easy, Safe & Reliable

TINAMU Tools designed for tough industrial environments

Plug & Play

TINAMU Automation without local setup, CAPEX, nor GPS

TINAMU Tools

TINAMU RMS light plug & play LiDAR kit

Tool-in-a-box for commodity monitoring indoor & outdoor on a drone or as handheld

✓ 6x faster inspections, 10x lower cost

✓ Digital twin, no installation, no investment

✓ Volumetric measuring, counting with algorithms

✓ Safe & efficient (no walking over materials, no operational stops)

✓ LiDAR (360°, 40m range) for tough environments

✓ Precise monitoring for metals, fertilizers, coal, rice, sugar, etc.

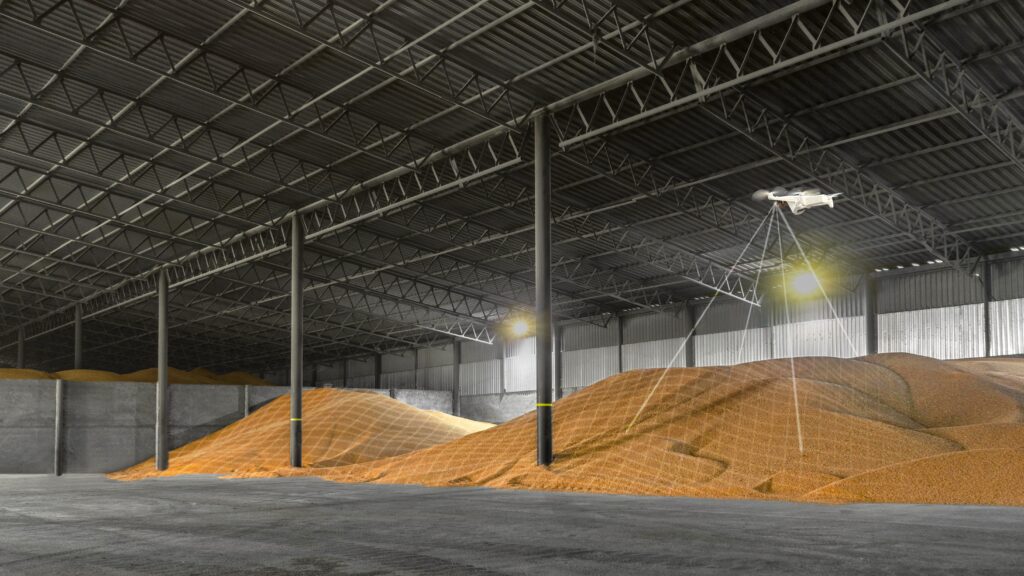

TINAMU RMS Automated Robotic Monitoring System

Automated indoor Inventory monitoring at the push of a button without GPS nor pilot

✓ Digital twins for traditional industries built from the air

✓ Data insights provided by flying flexible sensor platform

✓ Indoor navigation fully automated by computer-vision without piloting skills nor GPS required

TINAMU Automation

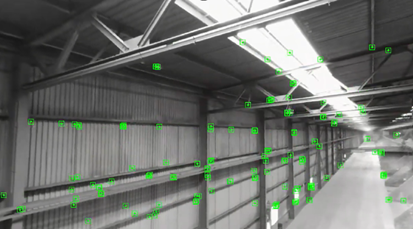

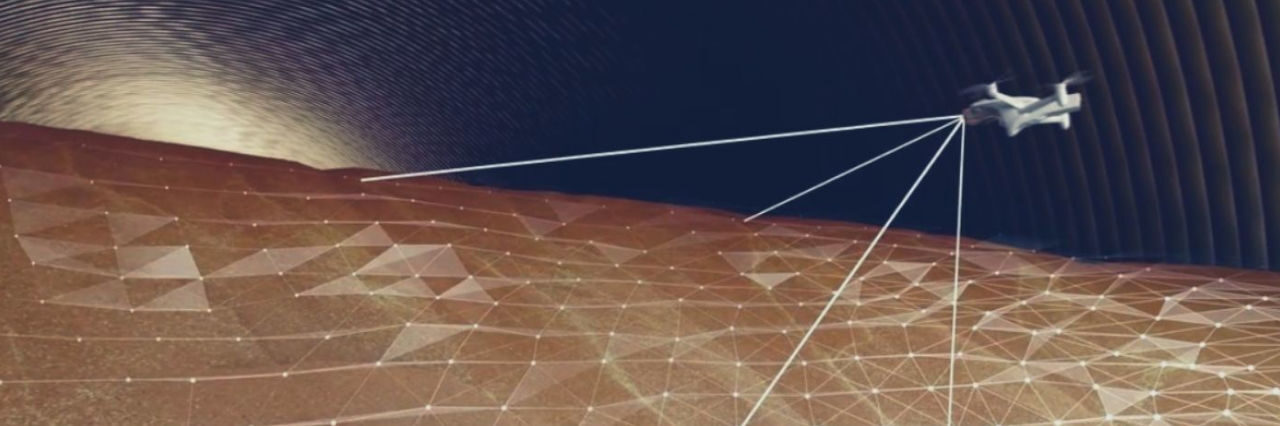

TINAMU Automated Navigation

TINAMU software makes drones fly automated without a pilot nor GPS

✓ Automated Indoor navigation by computer-vision

✓ Natural feature matched by TINAMU algorithm requiring no local installation

✓ Drone independent (adaptable & modular) and field approved (> 3Y operational at clients)

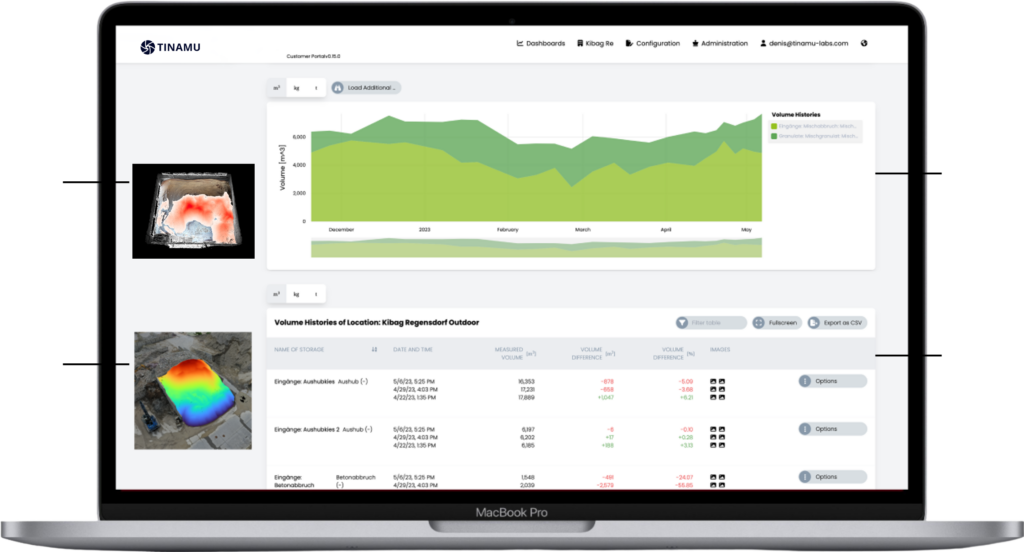

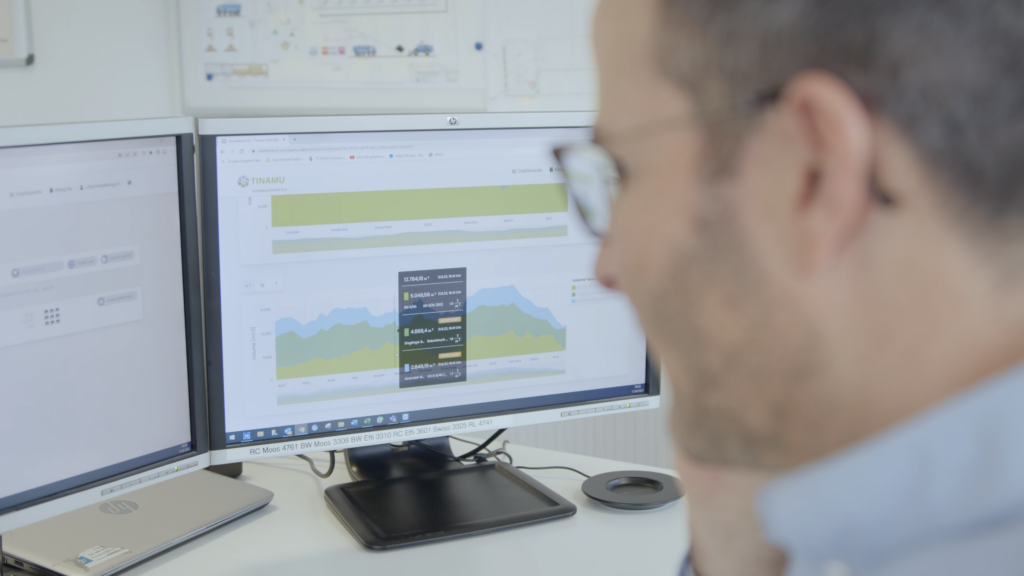

TINAMU Automated Cloud Processing

Standardized data insights through automated data pipeline

✓ Fully automated data processing for repetitive scans

✓ Assured trust, speed, and accuracy

✓ Traceable inventory changes over time

TINAMU Data Visualization

✓ Web-based platform to monitor and control inventories

✓ Custom-made reports (Excel, Word, PDF)

✓ Data insights integrated into customer system per API

TINAMU Analytics

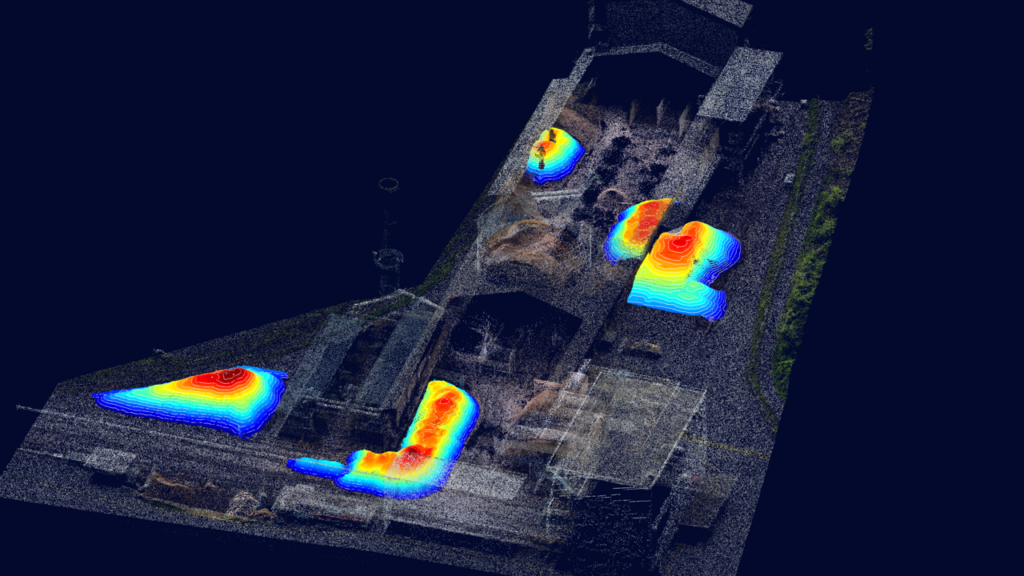

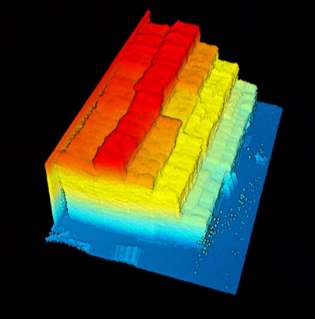

Volumetric Measuring

Precise, digital, fraud-free and real-time inventory monitoring

✓ Precise digital volumes (>99% accurary)

✓ Monitoring of movements, detection of changes

✓ Weight estimation with effective densities

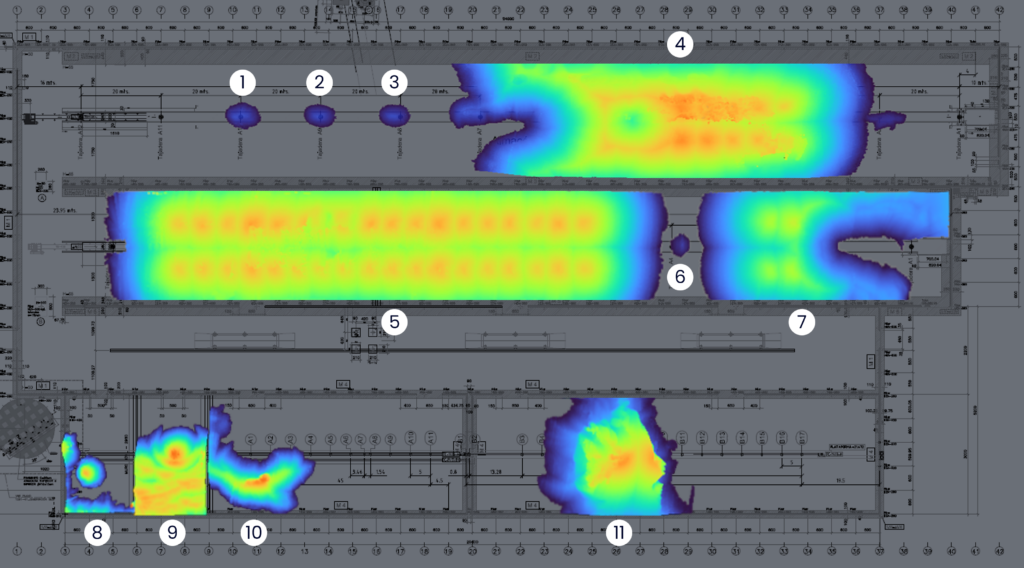

Counting

✓ Automated volumetric unit count

✓ Monitoring of movements and positions

✓ Algorithm-based object detection

Anomaly Detection

✓ Visual and thermal comparison of actual vs target state

✓ Automated semantic segmentation and object removal

✓ Precise position mapping

How It Works

Most stockpile inventories are done manually on paper, generating inaccuracy, errors, and safety risks. The process being long and repetitive, inventories are not done frequently enough. This leads to inefficient operations, planning, supply chain, profit loss, and carbon emission. Companies digitalizing their stockpile inventory with lidar, drones, and other devices struggle with a very time-consuming, manual and cumbersome process.

TINAMU provides an end-to-end automation solution allowing supply chain and inventory managers to get trust, visibility and control over their inventory in the cloud at the push of a button.

Industries

Metals & Minerals

A drone-based camera and LiDAR solution delivers transparent inventory overview – standardized, recurring, and in real-time

Soft Commodities

Bulk assets can be cumbersome or impossible to count. Yet, accurate and trusted inventory information needs to be available for asset owners. TINAMU offers end-to-end solutions for precise inventory monitoring

Traditional Industries

Automated digital twin for traditional industries built from the air powered by TINAMU analytics for construction site monitoring, visual inspection, and predictive maintenance

Case Studies

Operational Excellence at Construction Company KIBAG

Swiss construction company KIBAG leverages drone automation and advanced analytics for operational excellence.

Automated Stockpile Monitoring

Tinamu’s disruptive technology allows precise, fast and trusted inventories of indoor bulk warehouses!

About TINAMU

TINAMU is a spin-off from the Swiss Federal Institute of Technology Zürich (ETH Zurich). The team develops a turnkey solution for drone-based inspection automation that consists of a dashboard that visualizes relevant information, analytics software running on a secured cloud, and the drone system connected to a communication network. Real-time insights are directly delivered to the asset owners.

Meet The Team

Matthias Mock

CTO & Co-Founder

Get in Touch

Interested in innovative inventory monitoring?

Get in touch with our team today.

Copyright © 2018-2026 Tinamu Labs AG

Quick Links

Get in touch

-

info@tinamu-labs.com