Automated Inventory Monitoring

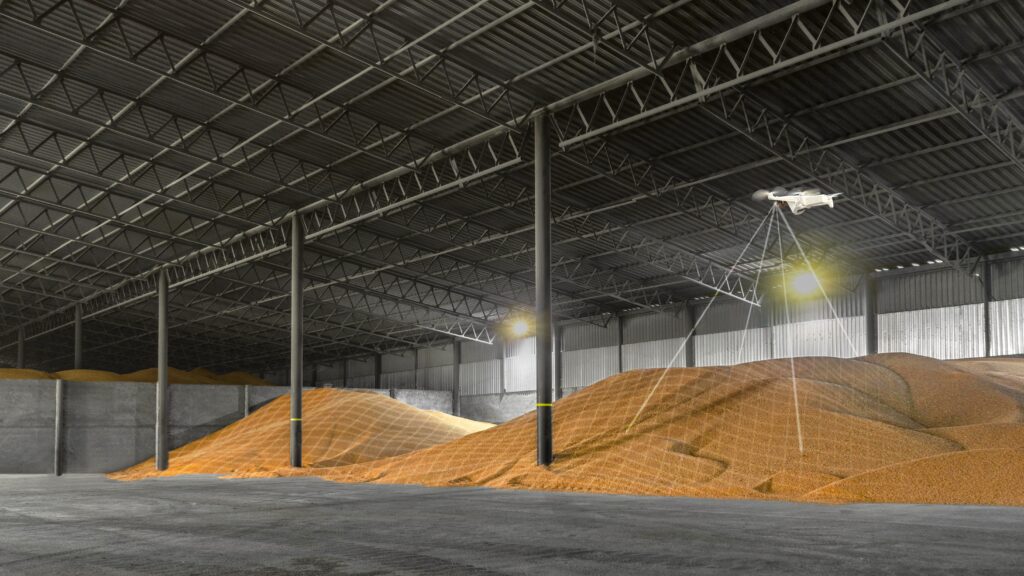

End-to-end automated monitoring for 24/7 visibility and control over your warehouse inventory. No pilot required.

Operational Excellence

Risk Reduction

Cost Savings

How It Works

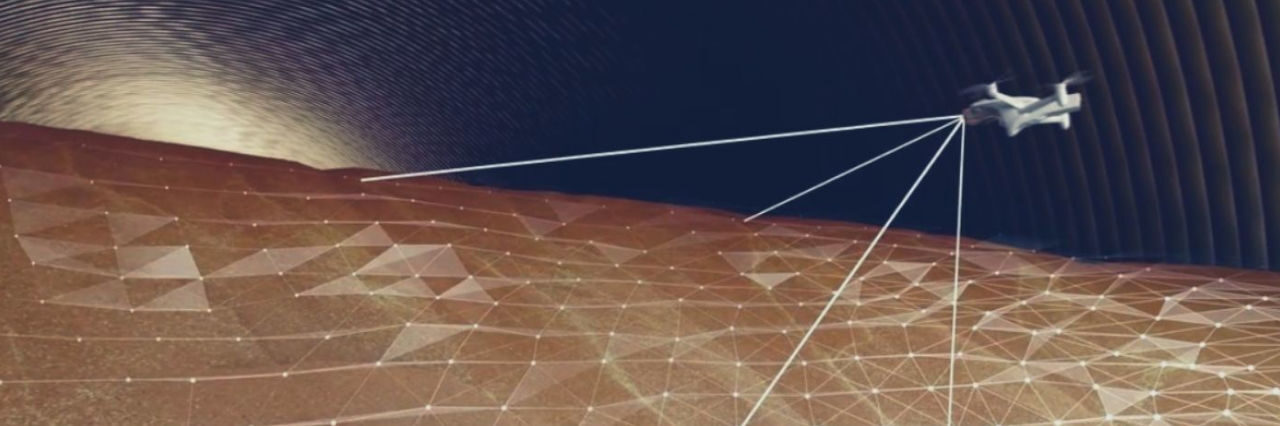

Most stockpile inventories are done manually on paper, generating inaccuracy, errors, and safety risks. The process being long and repetitive, inventories are not done frequently enough. This leads to inefficient operations, planning, supply chain, profit loss, and carbon emission. Companies digitalizing their stockpile inventory with lidar, drones, and other devices struggle with a very time-consuming, manual and cumbersome process.

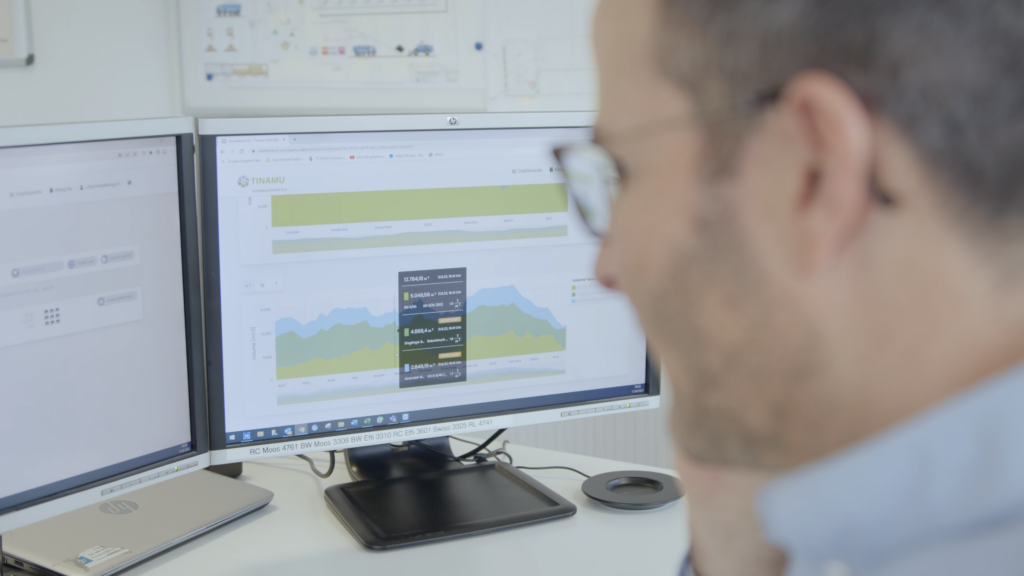

TINAMU provides an end-to-end automation solution allowing supply chain and inventory managers to get trust, visibility and control over their inventory in the cloud at the push of a button.

Industries

Metals & Minerals

A drone-based camera solution not only delivers invaluable inventory insights but also acts as a on-demand security camera where no angle remains unobserved.

Soft Commodities

Bulk assets can be cumbersome or impossible to count. Yet, accurate and trusted inventory information needs to be available for asset owners. Tinamu offers a end-to-end solution for this use case.

Construction

Conveyor belts are a perfect example of machinery which is hard to access and prone to failure if not inspected regularly. Using thermal images, we can automatically detect worn-out pulleys and, hence, reduce downtime of the overall operations.

Case Studies

Operational Excellence at Construction Company KIBAG

Swiss construction company KIBAG leverages drone automation and advanced analytics for operational excellence.

Automated Stockpile Monitoring

Tinamu’s disruptive technology allows precise, fast and trusted inventories of indoor bulk warehouses!

About TINAMU

TINAMU is a spin-off from the Swiss Federal Institute of Technology Zürich (ETH Zurich). The team develops a turnkey solution for drone-based inspection automation that consists of a dashboard that visualizes relevant information, analytics software running on a secured cloud, and the drone system connected to a communication network. Real-time insights are directly delivered to the asset owners.

Meet The Team

Matthias Mock

CTO & Co-Founder

Get in Touch

Interested in innovative inventory monitoring?

Get in touch with our team today.

Copyright © 2018-2023 Tinamu Labs AG

Quick Links

Get in touch

-

info@tinamu-labs.com