Solving inventory monitoring challenges with drone automation and AI

In this article, we will review

- why inventory monitoring is increasingly important?

- Why inventory monitoring is very challenging in industries like mining, agriculture, and aggregates?

- New stockpile measurement solutions

- How drone automation and AI address stockpile measurement challenges better than any other solution?

Why is inventory control increasingly important?

The need for better inventory management is not new.

Volumes need to be calculated to monitor how much material is present in the warehouse, mine, or production site, and matched with expected in and out-flows.

In recent years, this need for visibility and inventory control has intensified due to:

- Supply chain tensions and disruption

- Tensions on critical raw material and agricultural products supply

- Increased number of frauds (see recent fraud cases in the press)

- Growing ESG requirements

- The need to optimize storage space

Companies in the agricultural, mines, and construction sectors which are facing the complexity of inventory monitoring as explained above are even more subject to these pressures.

Moreover, visibility and transparency is not only required internally for sales and operations but also by external partners such as banks and trade finance institutions, insurance, and governments.

Why is inventory monitoring very challenging in industries like mining, agriculture, and aggregates?

Complexity and safety

Many of the bulk material in these industries are stored in stockpiles, outdoor or indoor in warehouses. This makes mining inventory management inherently complex and much harder than monitoring packaged goods, for instance.

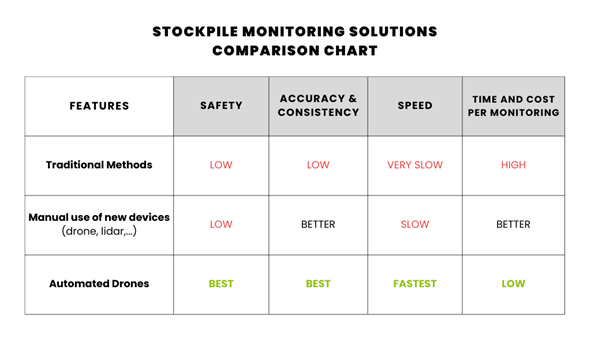

The safety risks are higher, in traditional stockpile measurement methods, surveyors usually need to climb stockpiles and access dangerous places. They are working next to trucks, loaders, and other heavy machinery which are very dangerous to operate around.

Time

Inventory tracking process for these industries are also time-consuming. Climbing stockpiles one by one and surveying and entire site can take several hours or days depending on the area size.

Loading that information back into Excel for data manipulation and volume calculation is also laborious and means that the results are only available multiple days after.

Accuracy

The process being very manual, the risk of errors in data manipulation and calculating is high. The final accuracy, as well as confidence in the data, are low.

Consistency with previous monitoring is also hard to maintain in such a manual process.

As a result, inventories are monitored infrequently, require a lot of time and effort, with only mildly useful information, usually merely just indications rather than actionable insights.

New stockpile measurement solutions

Digitization of the supply chain is advancing fast in the commodity industry.

Digitisation helps to better collect data

Lidar (light detection and ranging technology) is now widely adopted in inventory control systems and provides volume calculation much faster compared to traditional measurements. Since Lidar is now very accessible (to the point the latest smartphones include Lidar technology), surveyors have increasingly used this solution globally.

This process can be time consuming though, usually done by one or several surveyors, often spending a day or more on the site, to ensure accuracy, installing ground control points for instance.

Although it does add some accuracy, it is still a very manual process.

Photogrammetry is another technique that consists of building back 3D representation of a location by using multiple images shot from different angles. Drone surveys build such 3D representations by combining the images shot and the information on the location.

Data calculation solutions

Lidar and photogrammetry still require a person to export the data from the drone, download on a laptop and use software to perform volume calculation. This remains a labor-intensive manual process.

On the safety side, drone pilots are also subject to increased danger since they need to watch the drone in the air as well as at their screen in a dynamic environment full of trucks, loaders, and other dangers.

Consequently, even if new technologies are available, they remain long and dangerous and the stockpile monitoring is only done occasionally.

“ IF YOU CAN’T MEASURE IT, YOU CAN’T MANAGE IT “

Peter Drucker

Why automation is the future for inventory management?

Automated drones for stockpile measurement is the new way to optimize inventory management.

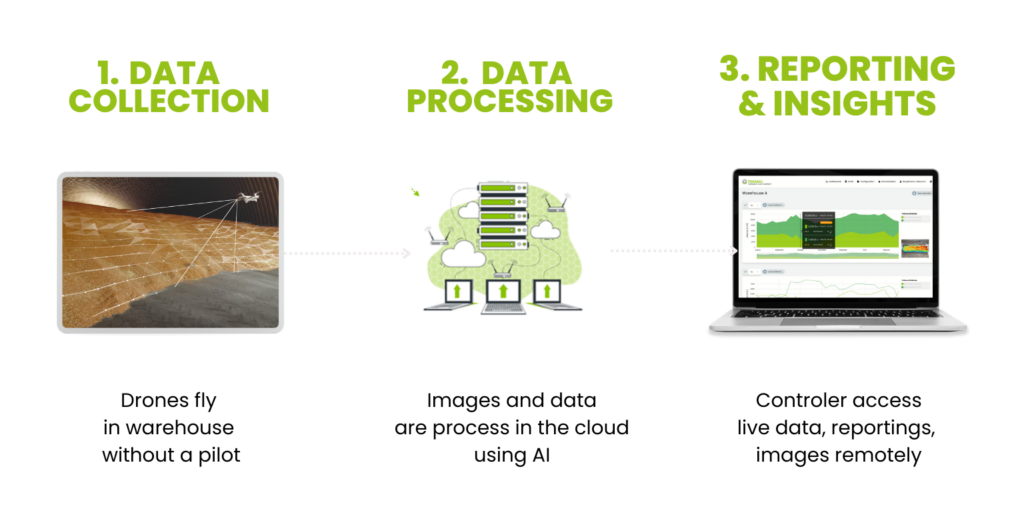

The automation of drones is enabled by machine vision to make them capable of self-navigating in warehouses, to follow a flight path in such a way that all stockpiles to be monitored are captured systematically.

Since the drone flies autonomously, the operator can be any employee, without any piloting skills or certification. The launch of the mission is done in one-click through an intuitive mobile application.

This means that the operator remains on the ground in a distant location, making this solution the safest of all.

Each flight in the warehouse (at Tinamu, we call this a “scan”) is a package of recorded data of the full premises, ready to go to the processing step.

The processing is done automatically on the cloud in a fast turnaround, with optional quality control. Stockpile volume will be automatically computed.

The last stage is the delivery of the data on our customer portal, adding insights such as graphical historical representations, visualization of volume changes and alerts for automatically detected discrepancies. Images of each stockpile of each previous scan can serve as evidence with regard to fraud and theft detection.

The data flow being periodic (weekly, daily), the inventory monitoring becomes an integral part of operations, accounting and finance, environmental processes, and much more.

Inventory planning is much easier, and the data is not only actionable, but it can also be used for predictive analysis.

To summarize, the main advantages of an automated inventory management solution are:

- faster measurement of stockpiles

- increased accuracy

- increase frequency

- Improved safety

For companies active in the mining, commodity trading, chemicals, and construction, there are many benefits of such efficient inventory control:

- Fraud and theft prevention and detection, with an extra layer of security and hard evidence images and data

- Frequent stock reconciliation

- Labour cost reduction in the inventory monitoring

- Operational savings such as machine downtime and maintenance costs reduction

- Better sales and production planning and forecasting

- Safety risks reduction

- Increase productivity and profits

- Improved financial forecasting and optimization,

- Asset-based financing, loans, and collateral management

- Reduce excess inventory

- Reduction of write-offs

- Better risk-management

- predictive analysis

- Better recycling and waste management

These benefits come on top of required reporting needs, for accounting reconciliation or regulation requirements for instance.

Compliance with new regulations such as mass balances requested by the EU Emission Trading System also require transparency, and accurate and frequent monitoring of stocks.

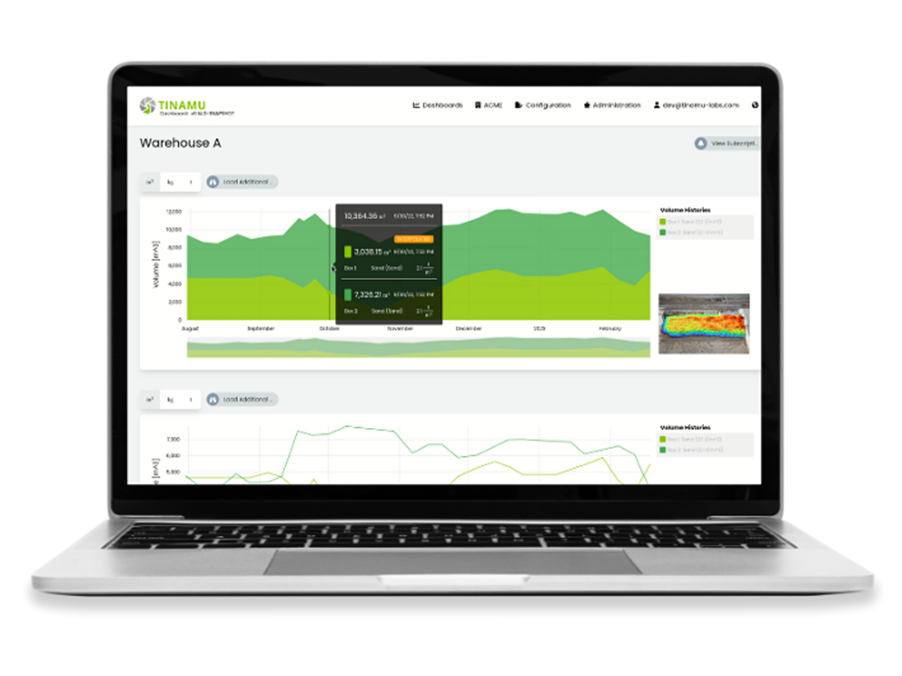

In Tinamu’s Customer Portal, customers dive deep into their inventory with detailed information on every stockpile, including trendlines, material distribution, and material differences.

Customers keep track of multiple stockpiles in the same warehouse, easily locating where changes have occurred, and making more informed decisions with the data aggregation feature.

The ability to access actual images of each stockpile add an extra-layer of protection against fraud and theft.

Conclusion

While old-fashion paper and excel based monitoring are progressively abandoned for better technologies, such solutions are still slow, very manual, somewhat inaccurate, and only marginally better in terms of safety.

The adoption of cutting-edge drone-based automated inventory management systems brings the industry in a much better position of trust, visibility, and control.

Would you like get more information about Tinamu’s

faster, safer and more accurate stockpile monitoring?